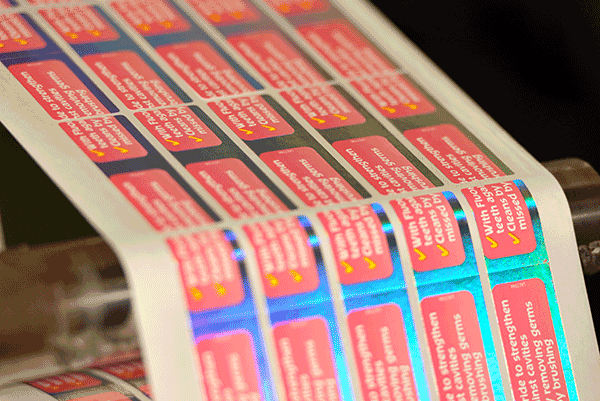

Cold foiling is a relatively new way of applying foil to labels via narrow-web printing machines. Our sister company, API Foilmakers pioneered the development of cold foiling technology which transformed the economics and flexibility of foil stamping in the 1990s. The process involves “printing” an ultra-violet (UV) curable ink onto the paper or board. The foil is then laid on by means of a nipping roller and then a UV lamp shines through the foil and cures the glue. The foil is then peeled off and rewound.

This is particularly suited for high volume, high speed label manufacturing applications. Our cold foils can be used with a variety of cold foil adhesives currently available in the market, including those supplied by Paragon Inks, another sister company of ours.